Description

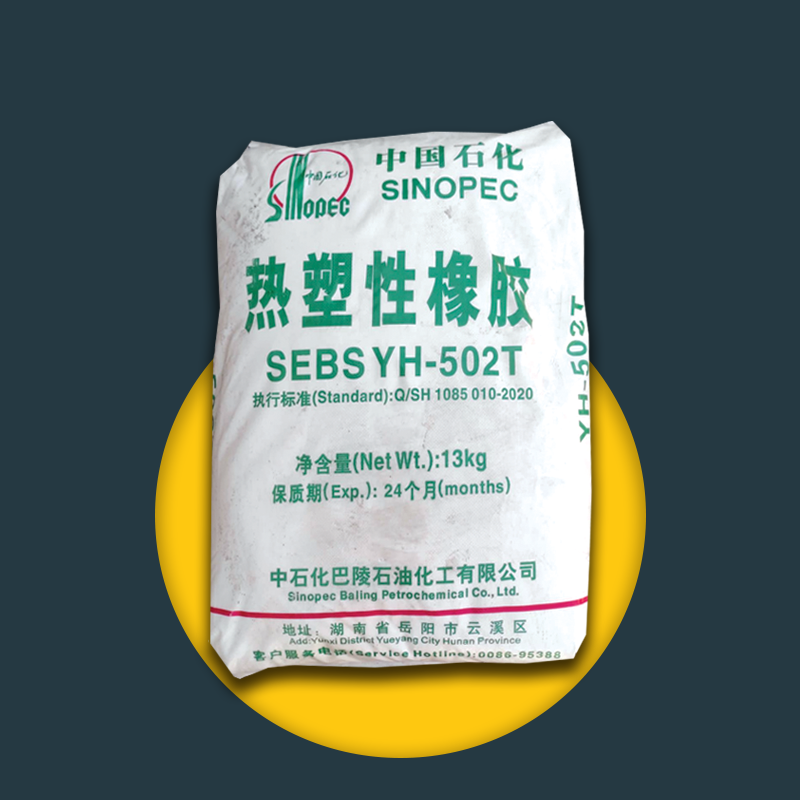

Brand: SINOPEC

Country of manufacture: China

Grade: YH-502T

Application :

These materials are used in many industries such as dental plastic equipment, toys, rubber balls, adhesives and sealants, shoes, bottles and containers.

What is styrene ethylene butylene styrene?

What is SEBS?

Purchase (Styrene Ethylene Butylene Styrene) known as SEBS is a type of thermoplastic elastomer (TPE) that is used in various industries. In recent years, this polymer compound has played an important role in the production of new plastic materials. SEBS polymer is one of the strongest and most flexible polymers and has high resistance to heat and sunlight. Addition of (styrene ethylene butylene styrene) improves the properties of polymer mixtures.

Styrene-ethylene-butylene-styrene (SEBS) is an important thermoplastic elastomer that behaves like uncured rubbers. This material is strong and flexible and has high heat and UV resistance and is easily processed. This material is obtained by selective and partial hydrogenation of SBS copolymer, which improves thermal stability, resistance to oil and weathering. On the other hand, hydrogenation reduces the mechanical performance and increases the price of the polymer.

This polymer is often used as a modifier or reinforcement of other polymers because this substance increases the resistance of other polymers and affects the properties of the final product such as its strength. In other words, the flexibility and resistance of the derivatives and compounds of this polymer against wear, heat, etc. is very high. In addition, the reactivity of polymer blends, especially in combination with petroleum-based oils, are more compatible with (ethylene-butylene) segments in SEBS polymers.

Three-component copolymers (styrene, ethylene, butylene, styrene) are produced through the hydrogenation of SBS polymer (styrene-butadiene-styrene), and are actually a type of thermoplastic elastomer obtained by adding styrene. Styrene polymers such as SEBS and SEB are the best polymer materials for the production of shoes and tires due to their good resistance to wear and tear. A wide range of suitable polymer properties of these materials have made them become the most widely used industrial materials.

This material has a special place in the international markets in terms of buying and selling, and meeting the needs of the domestic market of Iran is mostly done through the import of this product. Importing this polymer, in addition to providing it as an industrial raw material, plays a significant role in the production of high-quality and affordable final goods, and of course, the products that enter the Iranian market through Taiwan are of high quality.

Application of SEBS Styrene Ethylene Butylene Styrene

Use in the manufacture of some dental plastic equipment, children’s toys, rubber balls, adhesives and sealants, shoes, bottles and containers is one of the most common examples of the use of this polymer in the industry. It is also used in combination with other polymers to increase the strength of plastics, the efficiency of bitumen and asphalt, the production of compounding and other thermoplastic elastomers. Today, everyone cares about the fact that children’s toys are not pathogenic, in other words, they have food approvals and other standards for polymer products.

SEBS polymer is completely non-toxic and environmentally friendly and is safe for children. For this reason, many of the world’s leading manufacturers use SEBS-based polymers to make toys. In the field of medicine and health, SEBS-based plastics can guarantee the quality of products for consumers. This type of polymer is resistant to heat, water and weather and has become a substitute for PVC and phthalic acid in some industries.

The use of polymer (styrene ethylene butylene styrene) for the roof of the house is another example of the use of this polymer. Thanks to SEBS polymers, a new type of bituminous roofs has been released, which has several times better insulation than other old types (tiles and others). The use of this polymer improves the properties of bitumen and isogam, for example, the sensitivity of bitumen to sub-zero temperatures decreases, and its strength increases at temperatures above 100 degrees.

SEBS-based polymers are used to make electrical products, cable covers, pipes, and many materials used in construction, automotive industry, and other consumer goods such as washers, hoses, etc. Due to their high flexibility, these polymers are used to produce irrigation hoses, hoses capable of transporting chemical fluids and transporting liquid food products.

SEBS specifications

The important feature of this polymer is its compatibility with some mineral oils as well as polyolefins. This product has high resistance to heat and its strength against mechanical stress is higher than other polymers. Physically, SEBS polymer is in the form of a white powder that does not have a distinct taste or smell. The extensive chemical structure of these polymers consists of two parts: thermoplastic and elastic.

Its thermoplastic part is styrene and its elastic part is ethylene and butylene. The SEBS copolymer has a linear molecular structure and also has a high percentage of 1- and 2-vinyl structures. According to the type of molecular structure, its melting temperature is 205 to 245 degrees Celsius. These materials are still widely used in rubber and plastic industries due to their high reactivity, impact strength, high colorability, recyclability, and low price. The density of this material at 23 degrees Celsius is 0.9 to 1.3 grams per cubic centimeter.

The hydrogenated process (styrene ethylene butylene styrene) or in other words its chemical saturation makes it highly resistant to oxidation, ultraviolet rays and high temperature. Also, SEBS polymer made in the hydrogenation process has higher elasticity and thermal and mechanical resistance than SBS polymer. Due to the absence of SEBS links, this polymer affects the properties of the adhesive and increases its adhesion. These polymers are suitable materials for the design of pharmaceutical adhesives, and in this regard, the molecular weight of SEBS and the stability of its density are particularly significant. Derivatives of this polymer affect the biopharmaceutical function, i.e. the release of the drug and its permeability in the body, and research has also been done in this regard with ibuprofen tablets.

Reviews

There are no reviews yet.