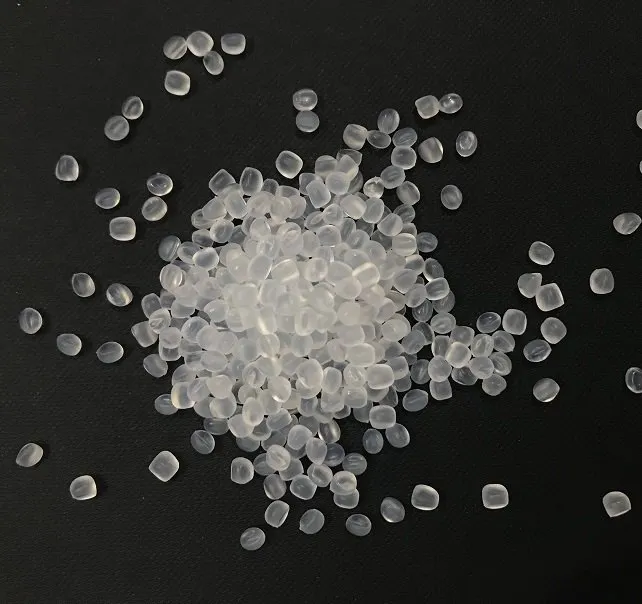

Impact modifier additives

Impact modifiers are added to many compounds to increase the toughness and impact resistance of the final products. So far, different groups of impact modifiers have been developed for different uses, and these additives increase the impact resistance of different products with different mechanisms.

The impact modifier corrects the inherent brittleness and brittleness at sub-zero temperature of the material and prevents the propagation of cracks, and the elastomer or rubber is natural and can absorb or disperse the impact energy.

Impact modifier features

- Improve impact properties

- Excellent weather resistance and good processability

- Uniform surface at high extrusion speeds

- Good thermal resistance

- Improved melt strength

- Low die inflation

- Resistance to bleaching against stress

- Good color stability

- Impact modifier applications

Automotive industry

- Electronic devices and wire and cable compounds

- Production parts with injection and blow molding

- foam board

- Door and window profiles

- electrical pipe (duct)

- Calendar sheet and film

- Pipes and fittings